Welcome to ReVPower Private Limited- manufacturers of high performance DC Motors

Leading Manufacturer of the DC Motors in India

Industries Served

Revpower produces customized solutions catering to the following industrial segments

BAR MILLS

STRIP MILLS

COLD ROLLING

SPONGE IRON

PIPE PLANTS

PRINTING

SUGAR MILLS

RUBBER PLANTS

Applications

- Bar Mill Stands, Shears, Pinch Rolls, Tail Brakes, Cooling Beds, Twi Channels, Block Mills etc.

- Strip Mill Reversible Roughing Mills, Continuous Stands, Vertical Edgers, Flying Shears, Pinch Rolls, Coilers etc.

- Cold Rolling Mills, Coilers, Pay Off Reels

- Sugar Mills, GRPF, TRPF, Batch Centrifuges, etc.

- Sponge Iron Kilns, Blast Furnace Skip Hoists, Cement Kilns

- Tyre Plant Banbury Mixers, Extruders and Calendars

- Battery operated motors

- All other kinds of standard and special applications for variable speed

Why Choose US?

If you place an order with us, expect a delivery within 2 months

Facilities Provided by Us

REV Power and its production facility are fully equipped to make cores, wind coils, wind rotors, and wind stators, as well as impregnate, cure, and perform all post-processing operations required for the rapid manufacturing of high-quality DC Motors. A well-trained and skilled crew is on duty to deliver the finest quality product and value to our customers.

If you order from us, you can expect your delivery within two months.

Production Facility

REV Power and its production facility are fully equipped to make cores, wind coils, wind rotors, and wind stators, as well as impregnate, cure, and perform all post-processing operations required for the rapid manufacturing of high-quality DC Motors. A well-trained and skilled crew is on duty to deliver the finest quality product and value to our customers.

Testing Equipment

For REV Power, it is necessary to conduct a thorough mechanical inspection on our DC motors to ensure the electrical motor's performance. It's also essential to test the motors under load in real-world stimulations to ensure that they operate within the acceptable temperature limits and have no malfunction.

How do we test our DC Motors in-house?

- Full load testing

- Testing at overload capacity–

- As per Class 4 and Class 5 Duty

Class 4: 125% overload for 2 hours

200% overload for 10 seconds

Class 5: 150% overload for 2 hours

200% overload for 15 seconds

- Temperature rise is limited to Class B and Class F

Class B: 70⁰C + ambient

Class F: 105⁰C + ambient

(All absolute temperatures)

News & Info

Latest company's news and blogs

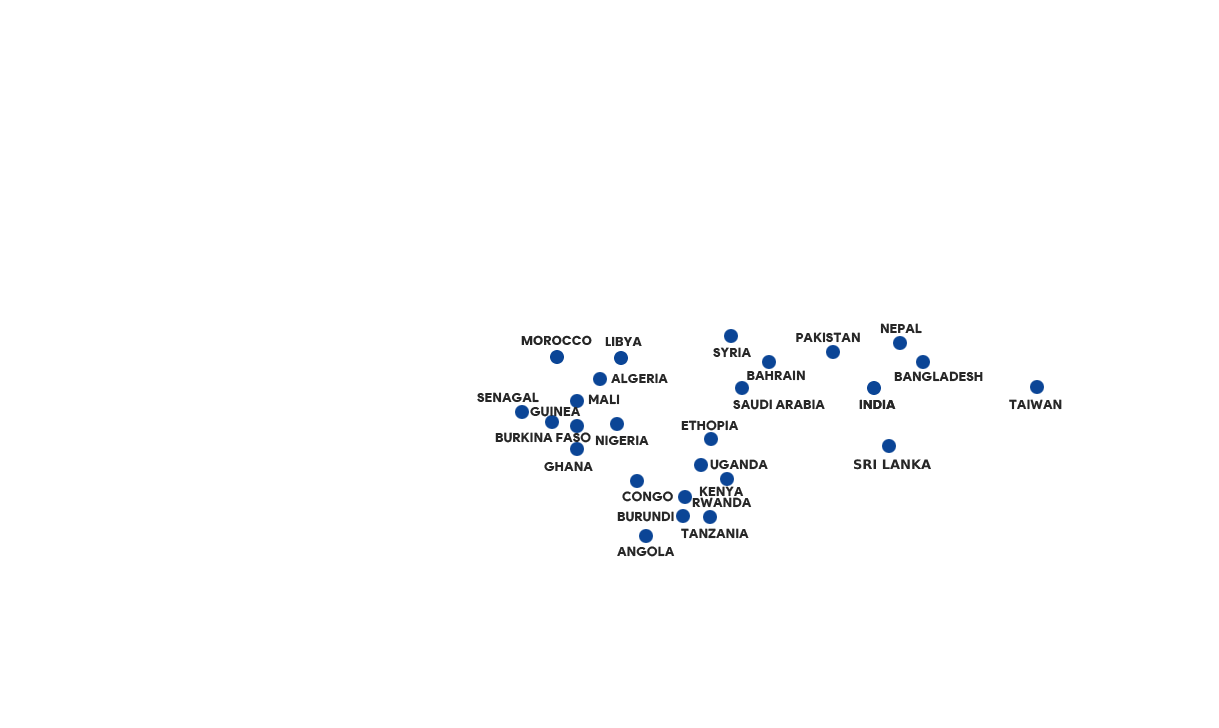

Our Global Presence

Latest company's news & announcements

Our Clientele